CNC Ball in a Box

I was in charge of opening the CNC room at Texas Inventionworks and developing a training curriculum for training students. I chose this project as a student training project and made one to test it out. The original inspiration is from the Titans of CNC YouTube channel.

Skills - CAM, CNC Milling, GD&T, Teaching

Doing a testrun

I like doing a test run in more forgiving material, when undertaking a complex CNC project. I did the first version of this project out of some scrap clear acrylic before moving on to the metal version.

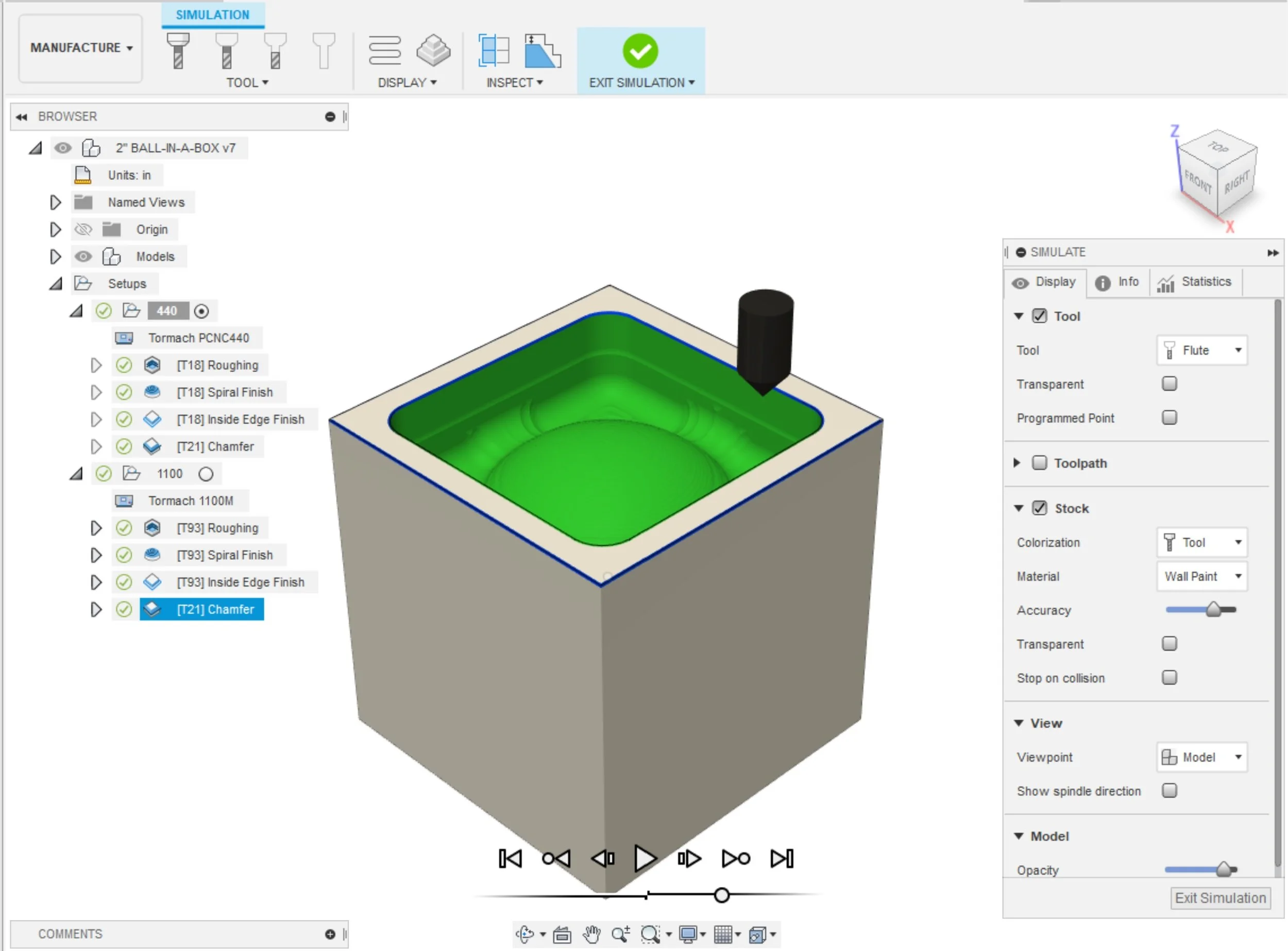

Writing some toolpaths

The screenshot is the final version of the CAM, for both the Tormach 440 and 1100 that we use in our CNC shop. There were many versions and changes made before getting this final CAM. There are 4 operations per side, roughing, spiral finish, edge finish, and a chamfer. The chamfer is optional and is the only operation that does not use a 1/4” ball nose endmill.

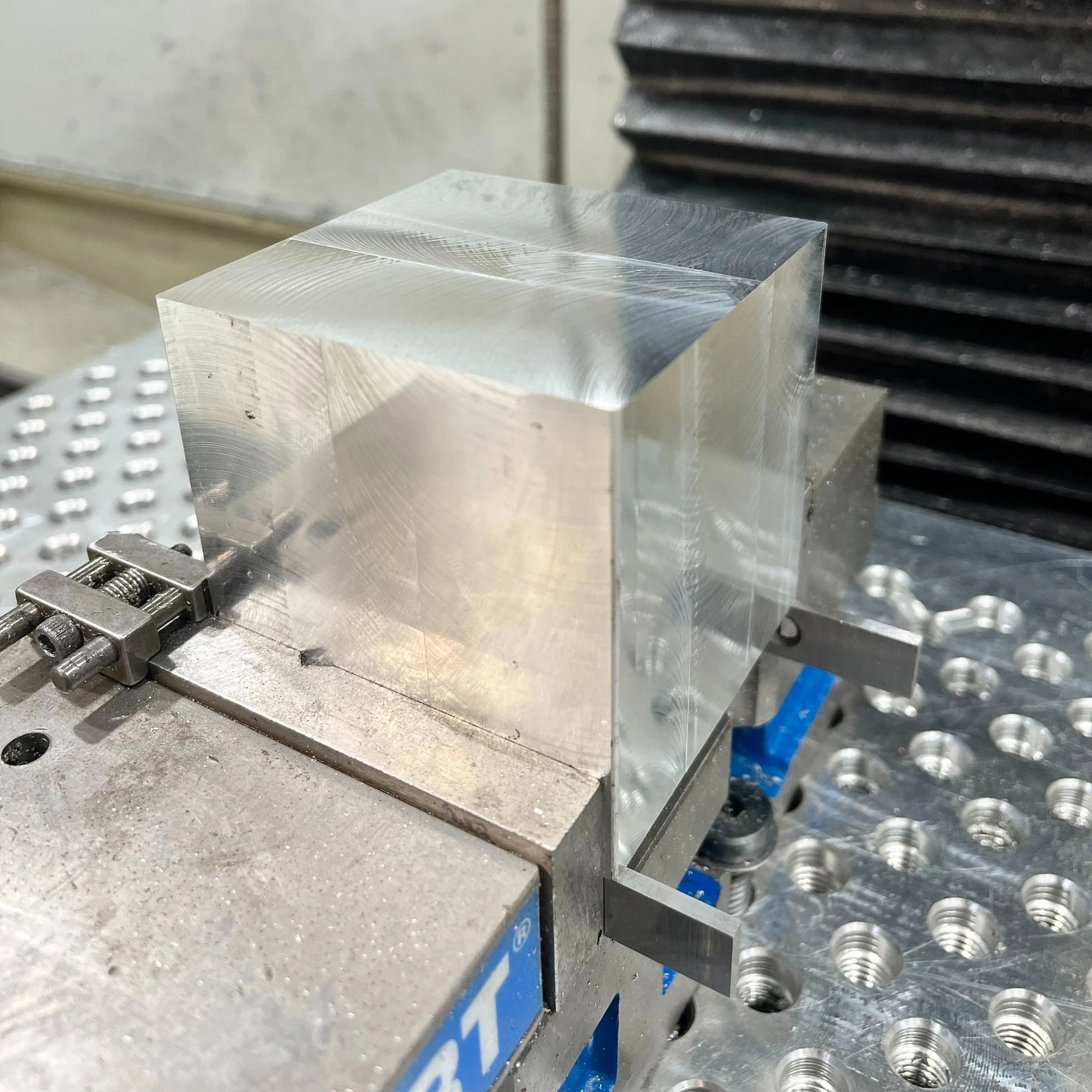

Squaring up stock

The project starts with a squared-up 2” or 3” cube of 6061 aluminum. The trainees are given a rough cut cube that they then have to face themselves so that they get practice with facing and also tolerancing.

Halfway done

Each face is machined with the 3-4 exact same operations then rotated and the process is repeated. The image shows the project half completed, with 3 faces machined and 3 faces left to machine.

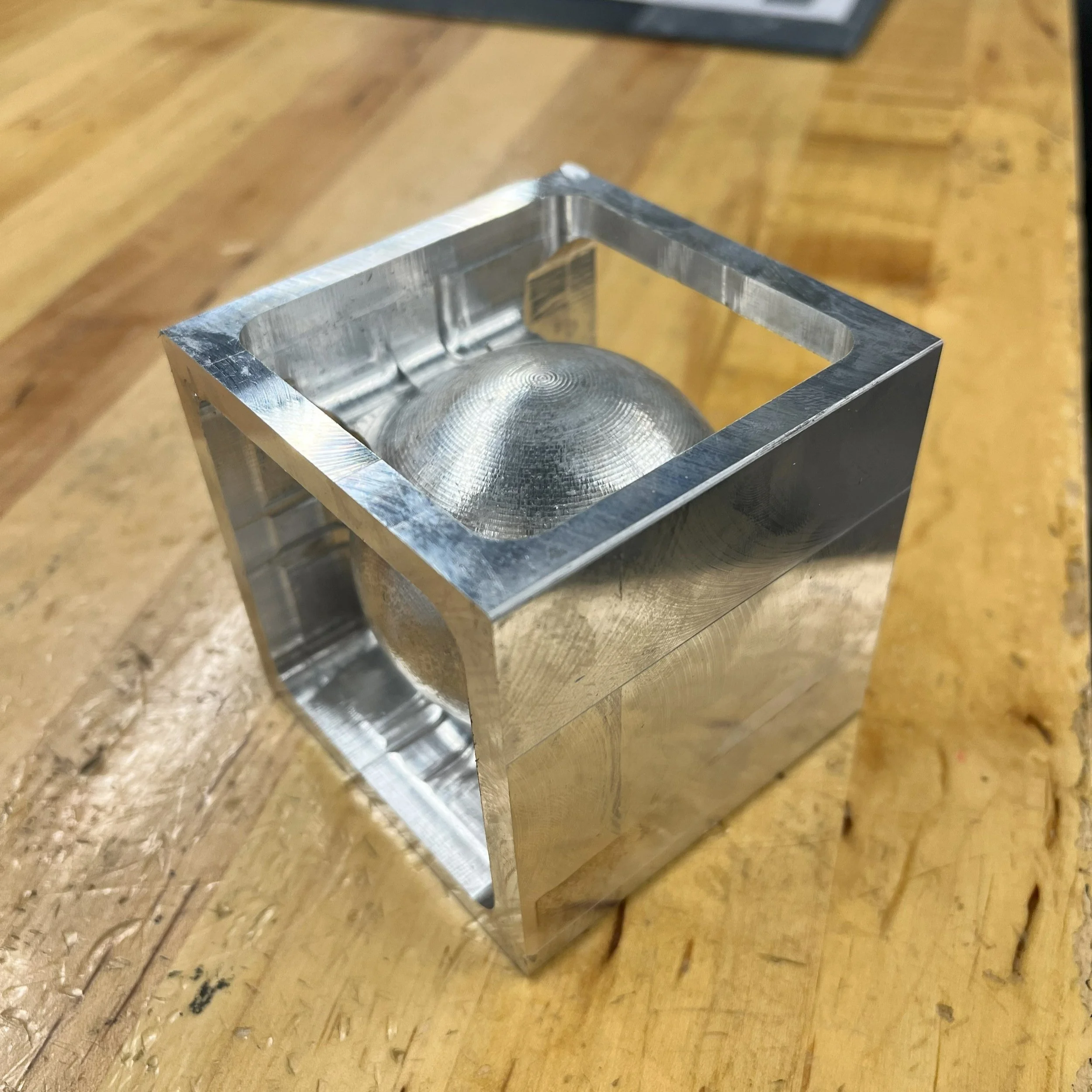

And its done!

The finished project is a sphere of aluminum that is disconnected from the exterior but trapped within the box. This project could have turned out a bit better if I used some better tools and spent more time on accuracy and tolerancing of each side but overall is a good project for students’ learning.